MIPP System: the sustainable revolution in the dairy sector

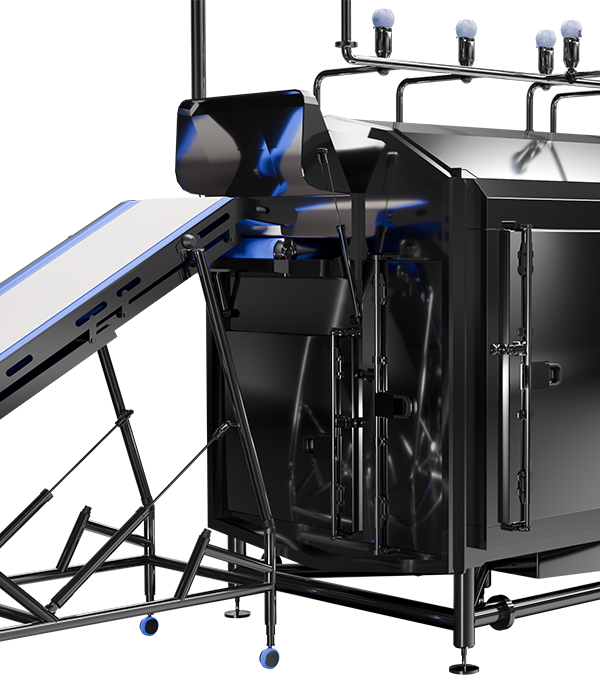

After a long journey of research, development and optimisation, Misotech™ presents MIPP System, a state-of-the-art plant for the processing of stretched curd that marks a concrete change in the dairy sector.

This internationally patented technology completely replaces water cooling with cold air cooling, offering high performance, greater sustainability and reduced operating costs.

What is MIPP System

MIPP System is an innovative solution designed to cool stretched-curd cheese without the use of water, completely eliminating water consumption in the post-stretching phase.

The system operates between milk processing and packaging, improving production efficiency, product quality and environmental impact.

Thanks to its modular structure, based on 500 kg/h units, it is easily scalable: starting from a capacity of 1,250 kg/h, the modules can be expanded (during the design phase only) and scaled to suit production needs.

Why choose air cooling

Traditionally, dairies use large amounts of water for cooling, generating high costs, waste and wastewater to be managed. The MIPP System introduces a more sustainable production model:

- Cooling with cold air: no water, zero waste

- Zero water consumption

- Superior energy efficiency

- Reduced environmental footprint

An ideal solution for modern plants, including those in areas with limited access to water resources.

The 10 concrete advantages of MIPP System

The process is reduced from 40 minutes to just 5–10 minutes: more speed, more cycles, greater productivity.

Compact design: from 150 m² to 70 m². Perfect for systems with limited space.

The system operates 24/7, with scheduled sanitisation every 3–4 days.

Advanced technology, fewer critical components, lower costs and greater reliability.

No frost or condensation on the product. Increased product stability.

Immediate processing, with no waiting times or mandatory maturation.

Automated system, also manageable remotely via PLC. Less staff, more control.

The perfect solution for plants in areas with limited water resources.

No loss during stretching. Higher yield, higher quality.

Uniform, clean shapes – ideal for automated packaging. Air cooling keeps products separate, without lumps.

A real alternative to traditional methods

Traditional water cooling systems show limitations compared to new technologies: they consume too many resources, require significant space and involve complex management. MIPP System represents a concrete turning point: it is modular, scalable, cleaner and much more efficient.

In the current context, in which environmental regulations are becoming more stringent and production efficiency is a competitive advantage, investing in MIPP System means choosing a technology designed for the future.

MIPP System: the future of the dairy supply chain is air

Choosing MIPP System means definitively abandoning the limits of the past and adopting a new production paradigm.

A sustainable, intelligent and profitable choice for those who want to stand out in the modern food industry market.